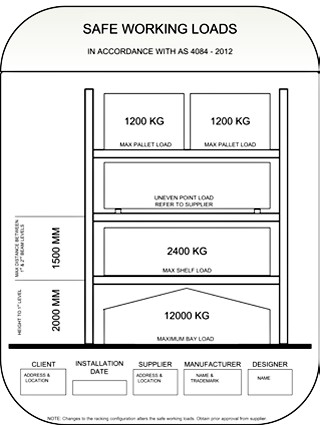

The rmi defines the height to depth ratio for a single row of pallet rack to be the ratio of the distance from the floor to the top beam level divided by the depth of the frame.

Warehouse racking specs.

We ve done projects for instance where long rolls of film or fabric can t be stored on cantilever arms because the arm would dent fragile materials and full support is needed.

Normal anchoring as is used for double rows is usually adequate for racks whose ratio is 6 to 1 or less.

It s easy to configure selective racks to fit your load size available space load weights and operational needs with this guide from cisco eagle.

You may already have pallet racks and want to adapt them.

Products returned as matches will meet all specified criteria.

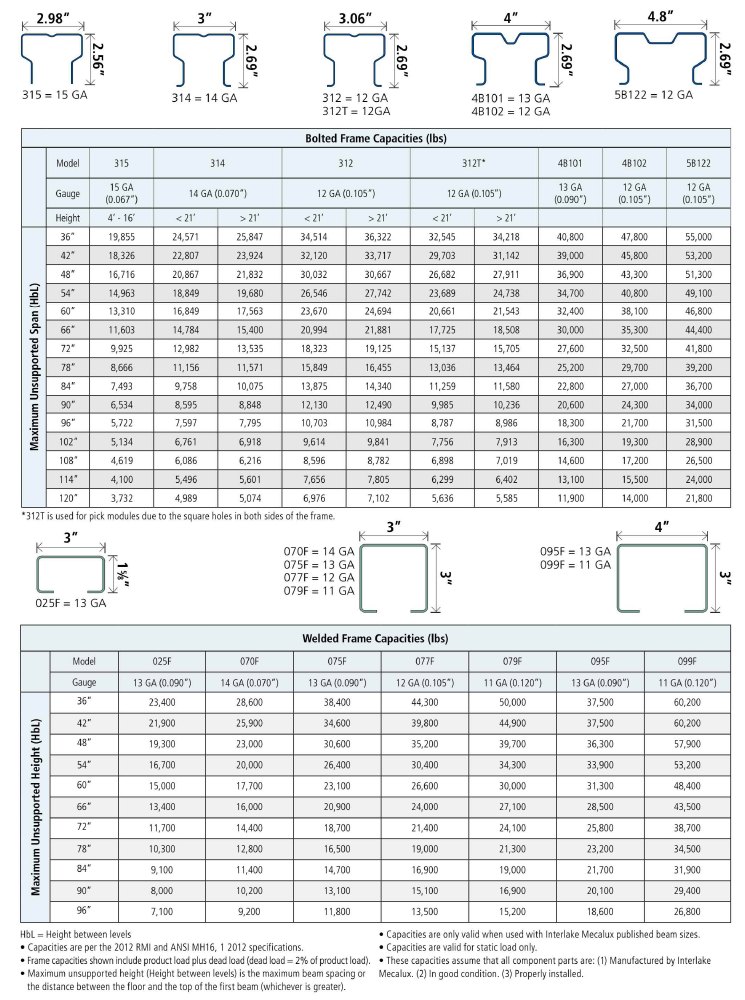

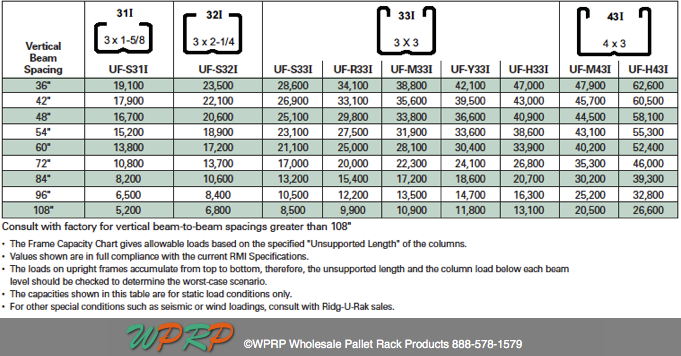

Capacity weight capacity is the maximum weight that the shelving racking can hold.

Pallet rack shelving can be configured for a variety of uses and product sizes.

If the height to depth ratio exceeds 6 to 1 the anchors and.

User may specify either both or neither of the at least and no more than values.

Any single row where the height to depth ratio exceeds 6 to 1.

One option is double depth racks which increase storage capacity by enabling four pallets to be stacked back to back requires a deep reach truck.

These must be checked for anchorage against overturning.

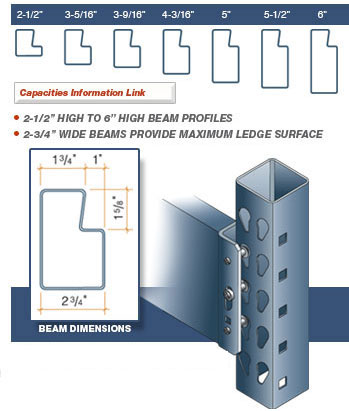

Depth depth is the distance from the front opening to the back.

Applications that involve support platforms or catwalks or any application other than normal pallet rack.

Model lgm 10 lgm 15 lgm 20 lgm 25 standard forks 9 ft 9 in 3m 14ft 7 1 2in 4 5m 19ft 6in 6m 24ft 4 in 7 4m length operating 57 1 2in 146cm 72 1 2in 184cm 80 1 2in 204cm 80 1 2in 204cm load capacity at 18.

Racks but there are applications where pallet rack fits better in the storage strategy of your facility.